-

Professional Version 4.10 – Further Information

IMST-ART is a simulation tool for refrigeration equipment of vapour compression type. It is completely devoted to assist the design and selection of refrigeration equipment and components. IMST-ART is able to perform parametric studies calculations, with different combinations of more than 80 design parameters. The graphical interface has been especially designed to provide a very easy input of data and a complete but comfortable analysis and postprocessing of the results.

The software allows for the evaluation of the working cycle for the prescribed components: evaporator, condenser, piping and compressor, at the given temperature and flow rate of the heat sources (secondary fluids). HEs can be prescribed just as an effective area and a given function of the overall heat transfer coefficient, or through a detailed 1D modeling which is able to take into account the HE type, flow arrangement and other factors. The compressor characteristics can be specified in a simple manner or by user-defined correlations for the isentropic and volumetric efficiencies. Pressure drop through every component is considered in the calculations.

Input of data:

- The components can de defined in different ways depending on the available information.

- User can select between IP/SI units

- The different components can be saved in independent files in order to provide a flexible tool for design.

- The components can be added to different lists. This utility lets the user perform calculations with different combinations of the elements just selecting them from the correspondent list. This makes IMST-ART a powerful tool for the selection of components.

- Compressors can be defined by correlations for the compressor and volumetric efficiencies. IMST-ART provides default correlations for the most common compressor types.

- IMST-ART lets the user perform calculations considering piping. Commercial sizes and materials can be selected for each pipe. Different insulation materials can be stored in a database and considered in calculations.

- IMST-ART provides detailed models for coils and plate heat exchangers which let the user know the evolution of the different calculation variables inside the heat exchangers.

- Different correlations from the open literature are available for the calculation of the pressure drop and the heat transfer coefficient.

- The geometry of the heat exchangers can be easily defined.

- Different materials for tubes and fins can be stored in databases.

- Pressure drops in capillary tubes, distributors and ports can be modeled.

- Different flow arrangements can be set.

Results:

- A complete table of results is displayed after calculations. The results are grouped by components and each column contains the results of every studied case.

- This tool is very useful for the results analysis. The table can be copied to the clipboard and pasted in other applications.

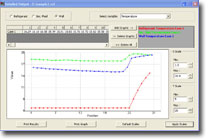

- IMST-ART provides an utility to plot graphs with any combination of the different variables and parameters.

- The user can access to the cycle information of every single case obtaining the thermodynamic properties of every point of the cycle.

- The results and the graphs can also be printed in order to be included in any documentation.

- The detailed output for heat exchangers shows the evolution of many different variables inside the exchangers. This is a very helpful tool for the design of the heat exchangers.

- Four different variables can be plotted simultaneously in the graph with different colors. The variables can be easily added or removed from the graph.

- All the scales in graphs can be changed in order to get the best representation.

Technical description & Hardware requirements